Smart Offshore Wind Operations and Maintenance – Creating Value from Big Data & Data Analytics

The current pace of renewable energy development worldwide is unprecedented, with offshore wind, in particular, proving to be an extremely valuable and reliable energy source. In June 2018, the global offshore wind portfolio stood at delivering 105GW when fully constructed.

Costs are critical for the future success of the offshore wind sector. The industry is pushing hard to make cost reductions to show that offshore wind is economically comparable to conventional fossil fuels. Efficiencies in operations and maintenance (O&M) offer the potential to achieve significant cost savings as it accounts for around 20% - 30% of overall offshore wind farm costs.

At the EDF Energy Research & Development (R&D UK), we are exploring how we can leverage the large amounts of data generated by our offshore wind farms at Teesside and Blyth to introduce cost-saving efficiencies to offshore wind O&M operations.

Existing offshore wind farm assets generate a significant amount of inhomogeneous data related to O&M processes, which contains valuable information that is currently underutilised. Leveraging the value of these large datasets, commonly referred to as “big data”, through a variety of analysis techniques can reveal patterns, trends and relationships that can be used to optimise operations and introduce efficiencies.

How can we define big data needs for offshore wind O&M?

Big data is typically characterised by the “4 V’s”- Volume, Variety, Veracity and Velocity. To best utilise big data concepts, the question that needs answering by analysing big data needs to be formulated. Some examples include:

- How can we reduce the amount of time we spend on planning O&M operations?

- How can we predict the failure of a major offshore wind turbine component in advance?

- How can we efficiently store spare parts?

- What tools can we use to decide when to sail or not to perform a maintenance task?

- What would be the best way to make maintenance vessels more fuel-efficient?

What types of O&M data are generated by offshore wind farms?

As offshore wind farms are unmanned and located far out in the ocean, they need lots of sensors to monitor their condition and performance. For example, a single turbine at Teesside offshore wind farm consists of more than 40 sensors, creating around 1500 individual data streams of information every day. In addition, information about daily maintenance operations, wind and wave information from meteorological masts and wave buoys, reports, pictures and videos from inspections performed are also logged.

How can we manage the O&M data?

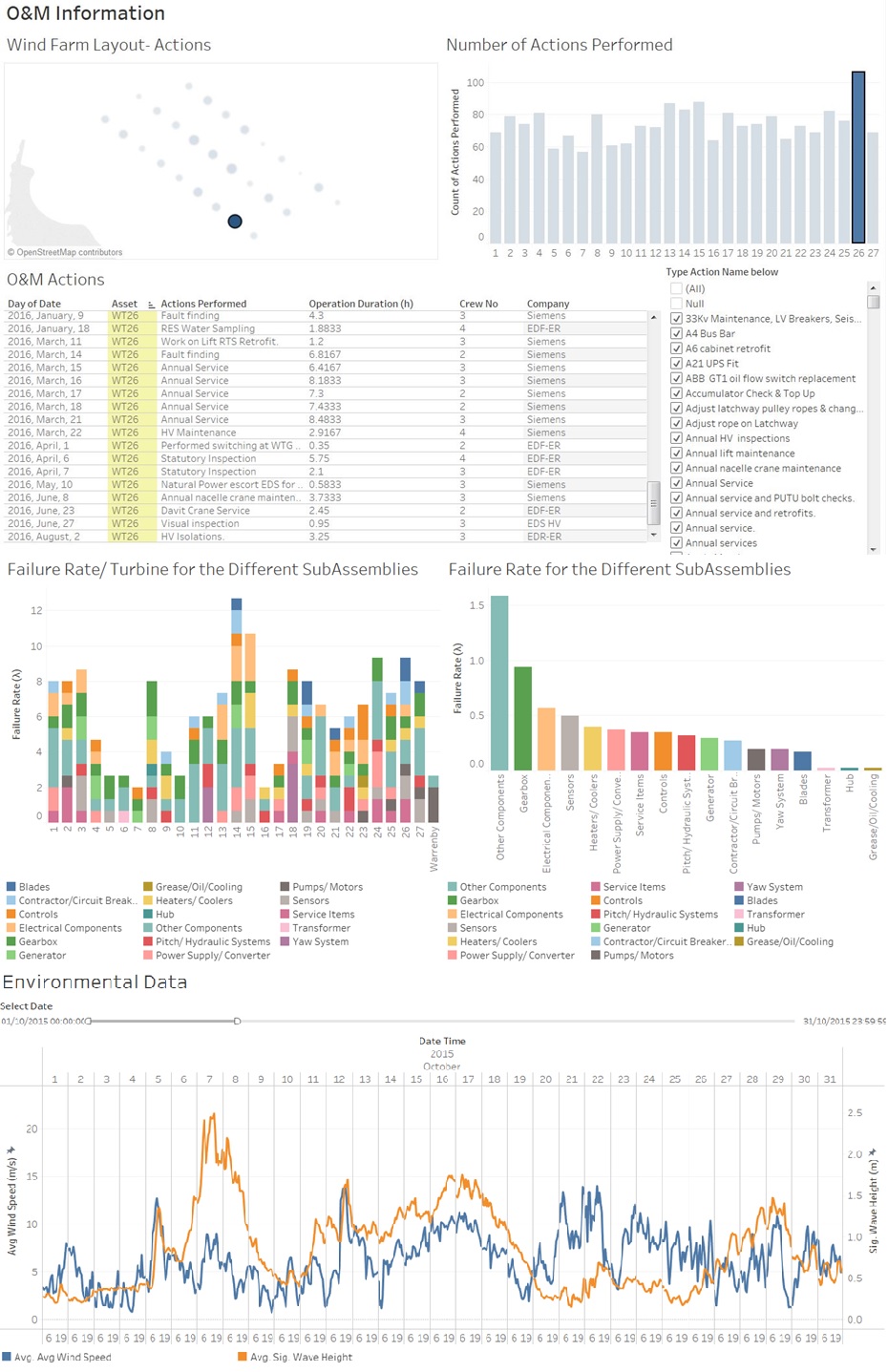

The data produced by offshore wind farms are generated from different platforms, stored in separate servers, in an array of formats, which make them be very challenging to manage. Therefore, it is almost impossible to derive conclusions about events, as it is very time-consuming to link the different relevant data streams. Thus, it is very important to implement structures and processes to manage and access these large datasets efficiently. The Renewables Team within the EDF Energy R&D UK Centre has come up with a solution to this problem by demonstrating a unified data management approach through the development of an offline database incorporating two years of O&M data from Teesside offshore wind farm, containing numerical and textual information about the wind farm.

This offline database demonstrates the following key concepts:

- A structure for organising the different sources of data from offshore wind farms.

- Visualisation formats to display critical metrics and trends.

- A single point of access for various data sources, allowing easy link between them and root cause analysis.

What can we do to leverage the value from O&M data?

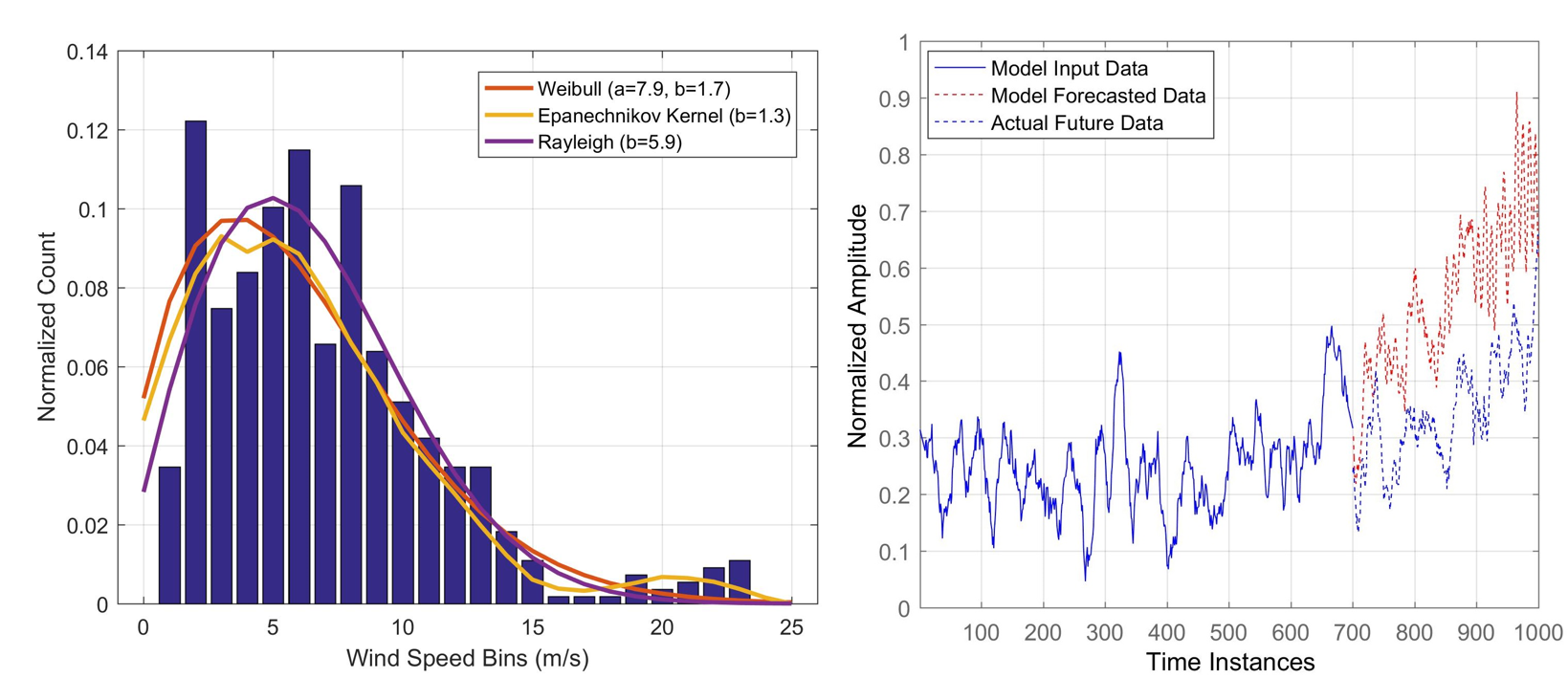

The best approach to gain the maximum benefit from a large dataset of O&M data is to employ data analytics. Data analytics is the science of examining raw unprocessed data in order to draw conclusions from it. Data analytics could take the following forms:

- Descriptive – e.g. visualising the offshore wind turbine’s condition from monitoring systems.

- Diagnostic – e.g. explaining the root cause of a fault or an alarm, reducing the time a technician needs to spend on the turbine in order to investigate it.

- Predictive – e.g. estimating the future behaviour of a sensor reading or forecasting the failure of a component well in advance.

- Prescriptive – e.g. providing information to determine the repair process to fix a fault.

The Renewables Team within the EDF Energy R&D UK Centre is leveraging the power of data analytics by applying numerous analysis tools to the offline database of O&M data from Teesside offshore wind farm. These tools built in-house, some with support of EDF R&D colleagues in France, help to showcase the ability to perform the root cause analysis of turbine faults, create useful key performance indicators (KPIs) and reliability statistics, diagnose faults and predict future failures and abnormal activities. In addition, the offline database of O&M data from Teesside offshore wind farm is being used to evaluate and rank the capabilities of commercial data analytics tools.

What is the state of the art of offshore wind O&M data analytics?

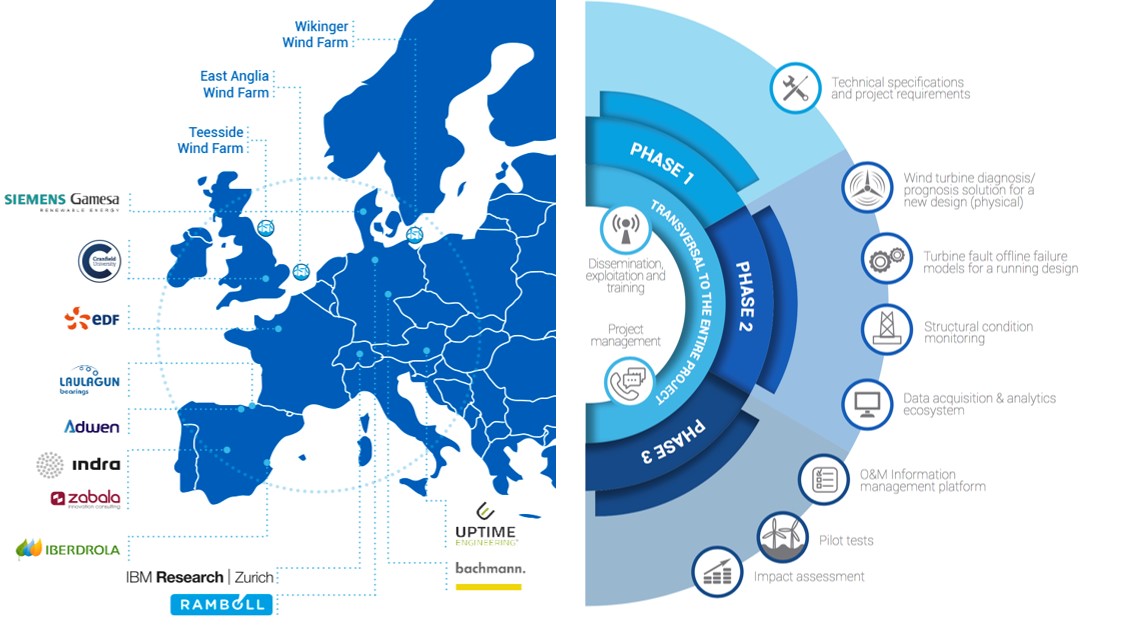

The future of smart O&M for offshore wind lies in developing a flexible Cloud and Internet of Things (IoT) platform that can provide an advanced analytics ecosystem. Here, failure diagnosis and prognosis models are built to better understand the real-time behaviour of the main components of offshore wind turbines under operational conditions; maximising their life span and minimising costs.

This in turn will help support reducing O&M costs of future offshore wind farms. The EU Horizon 2020 project, ROMEO, aims to achieve this objective and consists of a consortium of wind farm operators, manufacturers, IT companies, consultancies and Universities led by Iberdrola. The Renewables Team within the EDF Energy R&D UK Centre and colleagues from EDF R&D France are actively involved in this project to demonstrate a strong willingness to focus R&D efforts on data, reliability and cost reduction in support of offshore wind maintenance activities.

Related articles

EDF UK R&D Net Zero Heroes: Ruth

Exciting progress on hydrogen plans for Heysham 2